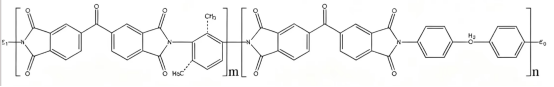

Zeshancheng-1212

Welcome to call for consultation on customization.

Welcome to call for consultation on customization.

product details

Zeshancheng-1212 Introduction

Zeshancheng-1212 is a thermoplastic polyimide micro powder with excellent solubility, dimensional thermal stability, creep resistance, high-temperature resistance, high toughness, and good machinability.

characteristic :

At room temperature, Zeshancheng-1212 micro-powder dissolves completely in N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAC), N-methylpyrrolidone (NMP), and m-cresol, with a solid content of up to 30%.

Zeshancheng-1212 micro powder, tested by DSC, has a glass transition temperature of approximately 313℃. Pure Zeshancheng-1212 profiles, tested by DMA, exhibit a glass transition temperature of approximately 335℃.

The Zeshancheng-1212 pure mold-pressed profile, tested using the TMA method, exhibits a thermal expansion coefficient of 41×10⁻⁶/℃. It demonstrates excellent dimensional thermal stability and creep resistance, making it ideal for enhancing the dimensional thermal stability of polytetrafluoroethylene (PTFE), bismaleimide, and similar profiles or components.

When Zeshancheng-1212 micro-powder is incorporated into thermosetting matrix resins or diluents, its particles undergo dissolution and swelling at 60-140°C through interfacial mutual diffusion. This facilitates uniform dispersion within the resin matrix. Upon curing, the resin forms a robust 'anchor effect' interface with the particles, enhancing stress transfer and absorption capabilities. Consequently, the material exhibits particularly significant toughness improvement.

Material application:

A, used to make parts for use in harsh conditions in various industries

B, a high-performance thermoplastic matrix resin with high-temperature resistance and exceptional toughness

C, for toughening modification of thermosetting matrix resin

D, for manufacturing high-temperature resistant insulating coatings and gas separation layers

E, used for manufacturing high-temperature resistant polyimide fibers and high-temperature gas dust removal systems